WATER & WASTEWATER SERVICES

CGRS has earned a strong reputation in the water- and wastewater-treatment community and we take the responsibility of delivering fresh, clean water to our community seriously with our water & wastewater services.

Oil and wastewater can both pollute drinking water, and the goal of systems for either fluid is to protect water supplies and clean up wastewater or contaminated water. CGRS has the skills and capacity to design plans and systems for protecting our water supply, including stormwater services, due-diligence investigations, remediation, regulatory compliance, UST/AST closure, environmental assessment and emergency spill response.

Design Engineering & Construction

We are able to draw on decades of design-build experience for the oil industry – combined with the knowledge, education and experience of staff members trained in the water/wastewater industry – to design and/or build top-notch water and wastewater treatment plants.

Our water and wastewater design and build capabilities include:

- Waterlines

- Pump stations

- Pressure release valves

- Check valves

- Tank valves

- Water systems

- Ditch diversions

- Hydrant installations/replacements

- Wastewater methane conversion to compressed natural gas (CNG)

Water & Wastewater Services: Project Spotlights

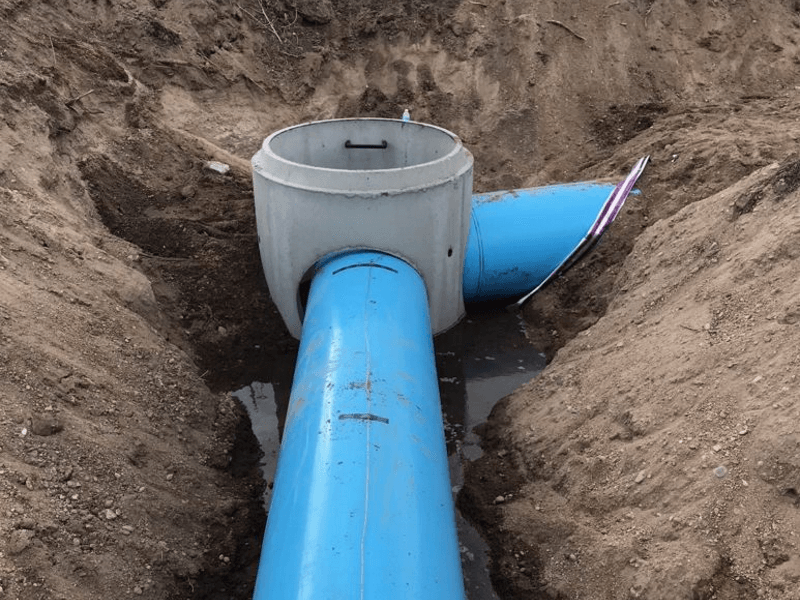

Heit and Koenig Infrastructure Project – Broomfield, CO

Heit and Koenig Infrastructure Project

CGRS’s Construction Services group worked on the Heit and Koenig Infrastructure Project for the City and County of Broomfield and the Central Colorado Water Conservancy District. CGRS won the project, designed by Sunrise Engineering, with a bid amount of $658,000. Our crew self-performed all of the work, which included all the trenching and backfilling for about 3,500 lineal feet of raw water pipelines that extend to the South Platte River northwest of Fort Lupton.

The PVC pipe installed included 18”, 24” and 36” pipe, along with installation of several 60” diameter precast concrete manholes. The project tied into a pump station project for the Central Colorado Water Conservancy District, also won by CGRS.

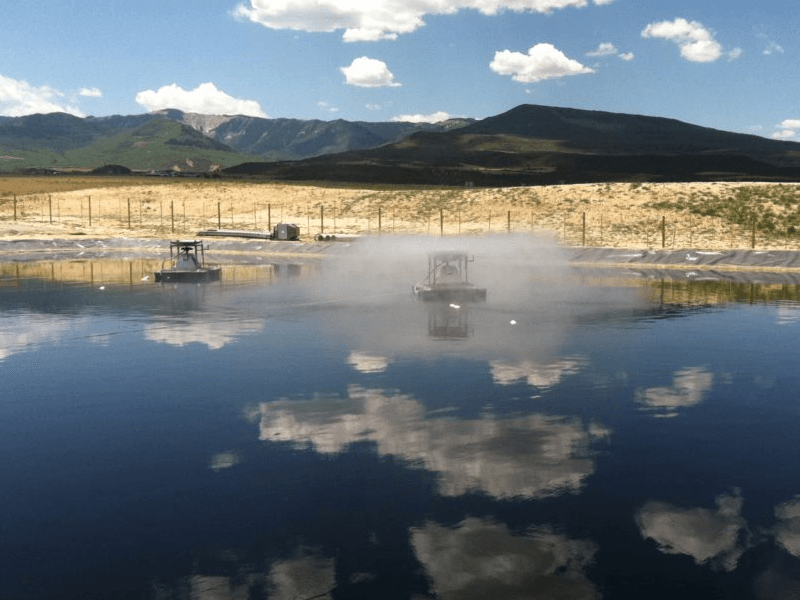

Design-Build Wastewater Plant – Rifle, CO

GreenBack Produced Water Treatment Facility

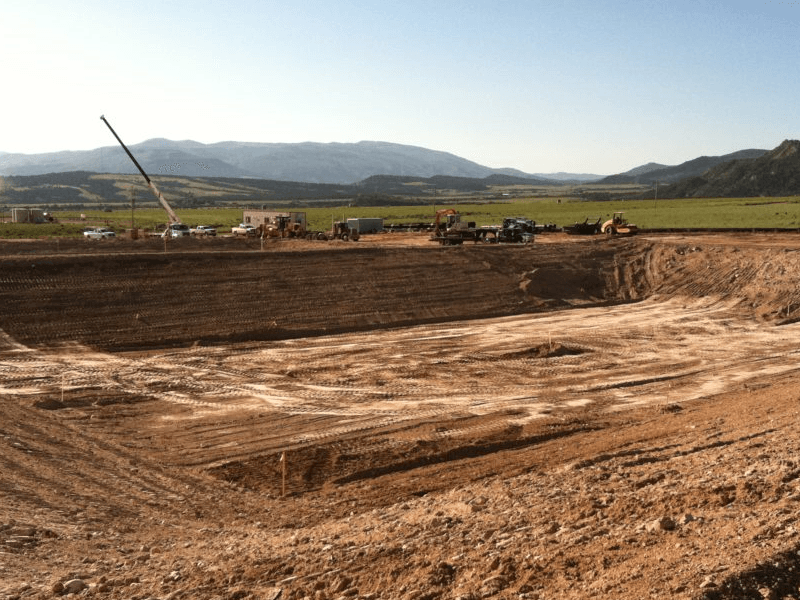

CGRS acted as designer-builder of the GreenBack Produced Water Treatment Facility in Rifle, Colorado. The facility was designed to accept wastewater from the production of natural gas and treat the wastewater to drinking-quality water for discharge to the Colorado River.

While contracted as the lead engineer and primary designer, CGRS also managed a team comprised of an architect, and fire, mechanical, electrical, automation and civil engineers. The system was fully-automated, including self-correcting system logic with dozens of pumps, sensors and recording devices.

Major construction components:

- Site grading and excavation of (3) double-lined storage ponds with a total capacity of 4.4 MG

- Two pre-engineered steel buildings, 5,760 square feet total, to house equipment and administrative offices

- Cast-in-place concrete sump with a total capacity of 40,000 gallons

- Installation of a 1,200-Amp electrical service, motor control center and PLC cabinet

- Dissolved air flotation

- IFAS bioreactor

- Dynamic sand filter

- Self-cleaning mechanical filter

- Tray strippers

- Regenerative thermal oxidizer

- Ultra-filtration and reverse osmosis

CGRS acted as the general contractor, overseeing earthwork, structural, concrete, electrical, and automation. CGRS acted as the mechanical contractor, constructing piping and setting pumps, tanks, controls, and valves. The project was completed on-time and within budget, with a total project cost in excess of $10,000,000.

Stormwater System Install – Loveland, CO

Loveland Fire Rescue Authority Training Center Retention Pond Mitigation, Storm Sewer System

CGRS acted as the general contractor for an environmental remediation project and construction of a new storm sewer system for the City of Loveland.

Major construction components completed by CGRS crews:

- Excavation of an existing impoundment, removal and disposal of petroleum-contaminated soil

- Excavation of a new water quality and detention pond

- Installation of new storm sewer consisting of several hundred feet of 18”, 24” and 30” RCP and 14”x23” HERCP

- Installation of pre-cast concrete structures, including manholes, a diversion inlet and sand/oil interceptor

- Constructed a micro pool water-quality structure along with an installed precast outlet structure with flow-control plates

With a state permit, the CGRS crew did extensive dewatering and treatment of the water through bag-and-cartridge filtration to be discharged to the sanitary sewer.

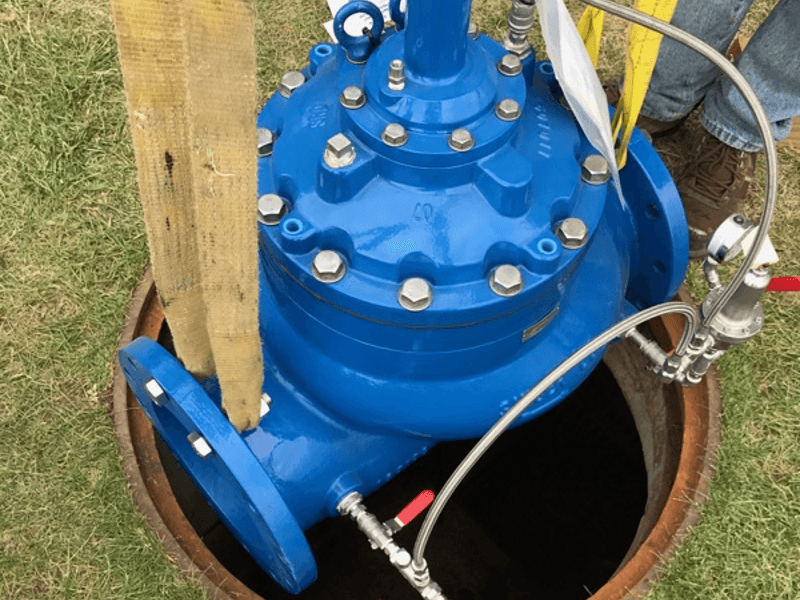

PRV Replacement – Northglenn, CO

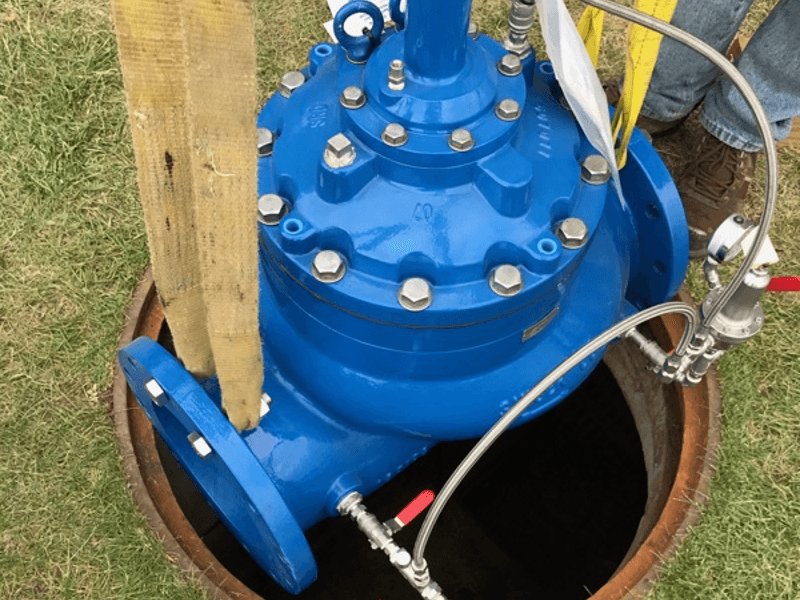

Northglenn PRV Project

The City of Northglenn contracted with CGRS to remove and replace three pressure reducing valves (PRVs) in their water-distribution system. CGRS personnel removed and replaced 4”, 8” and 10” PRVs located inside two underground vaults.

The 8” PRV replacement occurred under a strict time schedule, as water service was shut down to a residential cul-de-sac during the work. The CGRS crew accomplished the task ahead of schedule, and the overall project was completed ahead of schedule and under the original budget.

Major construction components performed by CGRS:

- Dewatering of vaults

- Health and safety assessment, ventilation of underground vaults, four-gas monitoring and non-permit required confined space entry

- Removal and installation of all existing PRVs and piping and installation of new PRVs, pipe, stands and restraint systems

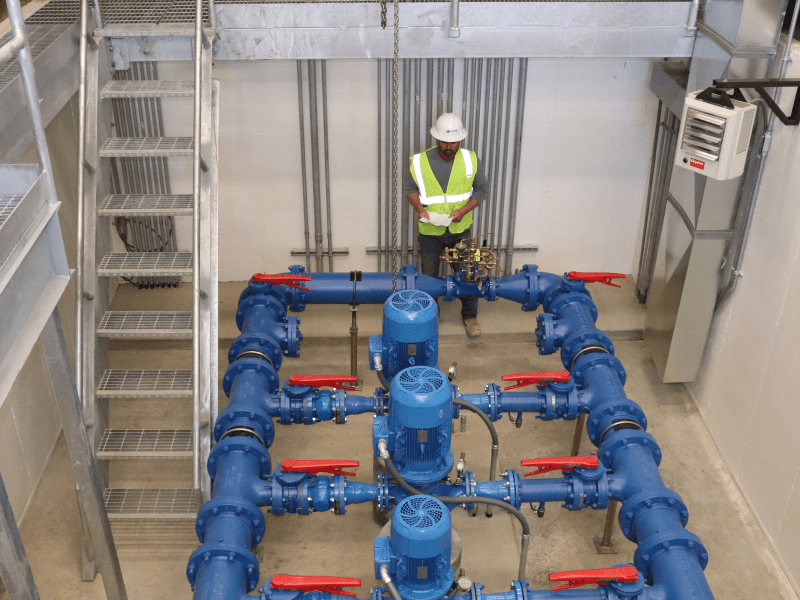

South Tank Pumping Station – Milliken, CO

Town of Milliken South Tank Pumping Station

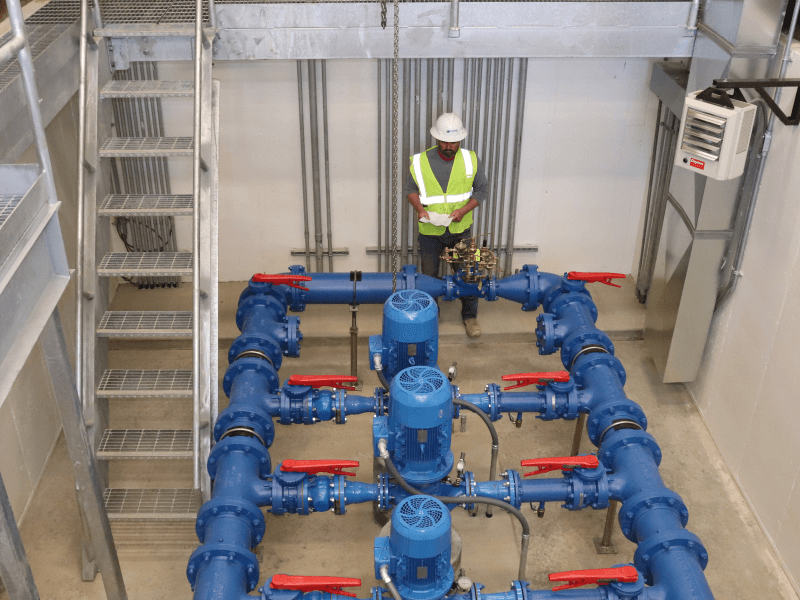

CGRS acted as the general contractor for a new pump station to serve the Milliken Town’s existing 1 million-gallon water tank.

Major components of the project included:

- Locate and tie to existing 16” PVC 905 water line to connect to new pump station, performed by CGRS crew.

- Building excavation, backfill and all exterior pipeline work performed by CGRS crew.

- Cast-in-place concrete foundation and 9’ basement level.

- Masonry building with engineered wood truss roof and standing seam metal roofing system.

- Pump system consisting of (2) standard service pumps; (1) high service emergency pump; (1) jockey pump and (1) submersible sump pump.

- Interior 4” and 8” ductile iron piping, associated valves and fittings to be constructed by CGRS crew.

- Associated electrical service and systems, variable frequency drives and automation to be installed by CGRS’ subcontractors and overseen by CGRS field superintendent.