LDAR & Regulatory Compliance

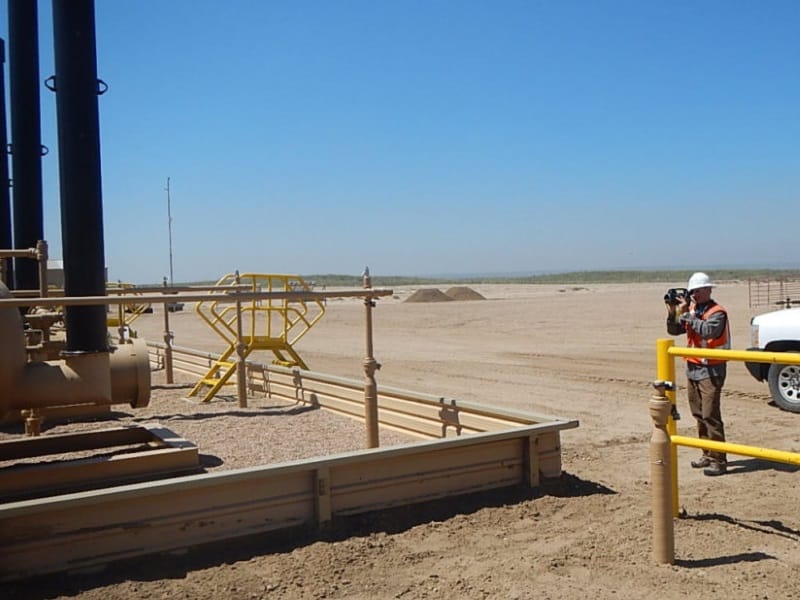

At CGRS, our Energy Services department contracts with the oil and gas industry to detect and reduce or eliminate fugitive emission sources according to the rules established by state regulatory agencies and EPA guidelines.

CGRS manages a highly efficient and effective Leak Detection and Repair Program (LDAR) for our clients, helping to reduce ground-level ozone and identify potential atmospheric releases of Volatile Organic Compounds (VOCs) and other Hazardous Air Pollutants (HAPs).

Using an infrared (IR) camera or Method 21 procedures, we identify emissions on all required components and on all applicable equipment. We can also complete simple repairs according to client protocols. Our LDAR reporting system is integrated with Connect®, our state-of-the-art data-management tool, allowing up-to-date reporting and client access to site-specific records.

LDAR

Audio, Visual, Olfactory (AVO) Inspections

CGRS incorporates audio, visual, olfactory (AVO) observations in tank battery facility inspections. Specific equipment observed during AVO inspection includes thief hatches, pressure relief valves, air pollution control equipment, auto-igniters, pilot lights, and piping. The AVO inspection seeks to document operational and non-operational equipment on-site in order to assist the client with applicable regulatory responsibilities.

EPA Method 21

CGRS uses EPA Method 21 to quantitatively detect VOC leaks from process equipment using portable detection instrumentation, such as a toxic vapor analyzer (TVA). This method involves placing a probe at the surface of every component interface where leakage could occur. Probes are moved along the interface while observing the instrument readout.

EPA Method 22

A human eye observation of E&P control equipment to measure timespan of emissions. Timed observations include qualitative determination of the presence or absence of emissions.

EPA Method 9 Observations

An observation of E&P control equipment to measure emissions over an established period of time by a certified staff member. Quantitative observations are recorded based upon opacity determinations at the emissions source.

Leak Detection and Repair (LDAR) and Storage Tank Emissions Management (STEM), Oversight and Inspections

Many state and federal regulations require LDAR and STEM as part of the emissions reduction strategy. CGRS conducts site inspections using approved instrument monitoring methods (AIMM), develops formal state-required plans, and determines applicable inspection frequencies. Tracking of fugitive emission tags and regular reporting is done on a timely basis, per state and federal requirements.

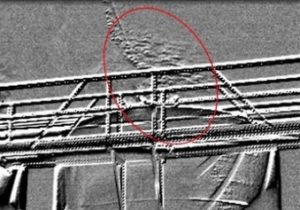

Optical Gas Imaging (OGI)/IR Camera Inspections

An infrared camera sees what the naked eye cannot. The use of an infrared camera is an approved instrument monitoring method (AIMM). These cameras are used to observe and record volatile organic compounds (VOCs), methane and other natural gas leaks from E&P equipment. Pictures and videos captured by CGRS provide clear footage of the emissions and assist crews with repairs.

Naked Eye

Standard IR Mode

High Sensitivity Mode

Regulatory Compliance

Colorado Regulation 7 and Downtime Reporting

Colorado Regulation 7 system-wide condensate tank reporting requirements mandates documentation of production and control equipment downtime on a semi-annual basis in order to document an operator’s system-wide control strategy for sites with calculated emissions of greater than 2 TPY VOC.

Colorado Storage Tank Emission Management System (STEM) Plan Preparation

A detailed plan explaining the management approach for control of storage tank emissions is generated by calculating calendar and rolling 12-month annual VOC emissions, weighing the data against three qualifying scenarios and calculating the resultant inspection frequencies. The STEM plan is produced with spot-on detail for every tank battery facility. Regular reviews and plan management are included.

Compliance Evaluation

CGRS offers full service site inspections, along with detailed compliance evaluation reports identifying state and federal regulations and how they apply to a site. We work with our clients to develop a comprehensive compliance strategy for each site to ensure every applicable regulation is addressed.

E&P Site-Specific Sampling (Oil, Natural Gas, Production Water)

Samples are collected using pressurized piston cylinders in order to calculate emissions for point sources. Site specific emission factors are generated from field samples that allow for a more precise and efficient permitting process. Bubble point technology and strict adherence to sampling protocols ensures a high level of sampling integrity.

E&P Waste Management Plans

The management of E&P wastes should occur in a manner that prevents releases of hazardous constituents to the environment, particularly releases that may impact groundwater and surface water resources. Waste management plans are an important component of any operation, from initial drill cuttings management through wastes generated from on-site activities. Let CGRS create an effective plan that will emphasize waste minimization, and, in turn, promote a more effective waste management solution.

Emergency Response Planning and Management

Creating an Emergency Response Plan that incorporates the clients existing EH&S practices with the state and local regulations for emergency response situations and incident command practices.

Facility Response Plans

A facility response plan is required when Federally established criteria are exceeded with respect to storage capacity at your facility, and other factors that increase the danger of your facility contributing to impacts to the surrounding environment and waters of the state.

Floodplain Plans

The State of Colorado experienced devastating flooding in 2013, which resulted in a stronger focus on a tank battery’s ability to withstand floodwaters and higher than usual rainfall. With a focus on 100-year floodplains, CGRS provides state-required site-specific floodplain plans in compliance with COGCC rules. These rules increase equipment stability, and implement greater steps to prevent contamination of our lands and waterways should another flood event occur.

Flowline Helium Leak Locate

Difficult decisions need to be made when a flowline test indicates a leak. In addition to handling regulatory implications, CGRS is able to offer a cost-effective solution that provides an alternative to excavating long stretches of flowline in order to find and repair the leak location. CGRS is able to utilize our patented helium leak locate technology to pinpoint the leak and avoid spending the time, money, and effort with conventional methods or deciding to shut in the well indefinitely. As one of your operations partners, allow CGRS to pinpoint the leak and get the well and flowline back into operation.

Flowline Integrity Management Plans

The Colorado Oil & Gas Conservation Commission (COGCC) requires all flowlines that operate at greater than 15 psi be pressure tested to the maximum anticipated pressure each year. They also require that a flowline management plan be created to track the historic testing details of all flowlines. CGRS delivers on-site pressure testing using high capacity equipment, and a variety of gas and liquid testing materials. With over 25 years of line testing experience, CGRS is a trusted name in flowline management and compliance.

In Colorado and surrounding Rocky Mountain states flowlines may be required to be pressure tested before initial operation, after a repair, and on an annual basis. With over 25 years of flowline testing experience, CGRS is able to provide you with a flowline integrity management program that will keep your facilities current with applicable regulations.

Using a trailer specifically built for the task, CGRS has the ability to pressure test your flowlines and record any degradation in pressure level for the duration of the test. CGRS will test each line per applicable requirements and is able to test lines at a wide variety of pressures to ensure a proper test. CGRS will manage the testing and documentation for each flowline across all facilities as part of the flowline integrity management program. WE will handle the regulatory audit process for you and supply all required testing results. As you regulatory partner, we will communicate testing schedules and results to that you are up to date on the integrity of your system.

Spill Prevention, Control, and Countermeasure (SPCC) Plans

Spill Prevention, Control, and Countermeasure is a federally required plan for sites with oil storage capacity in excess of 1,320 Gallons (~31 BBLs). These plans ensure that secondary containment is properly sized and constructed to mitigate spills, and to implement the notification hierarchy required to address spills of incremental magnitude. CGRS conducts on-site inspections, develops the SPCC plan, and completes a detailed review process, including the approval and signature of a Professional Engineer.