LDAR Inspections: CGRS has them down to a science

When a national company experienced high attrition among its northern Colorado in-house staff, it enlisted CGRS to provide various leak detection and repair (LDAR) services for a number of its facilities as an effective long-term solution.

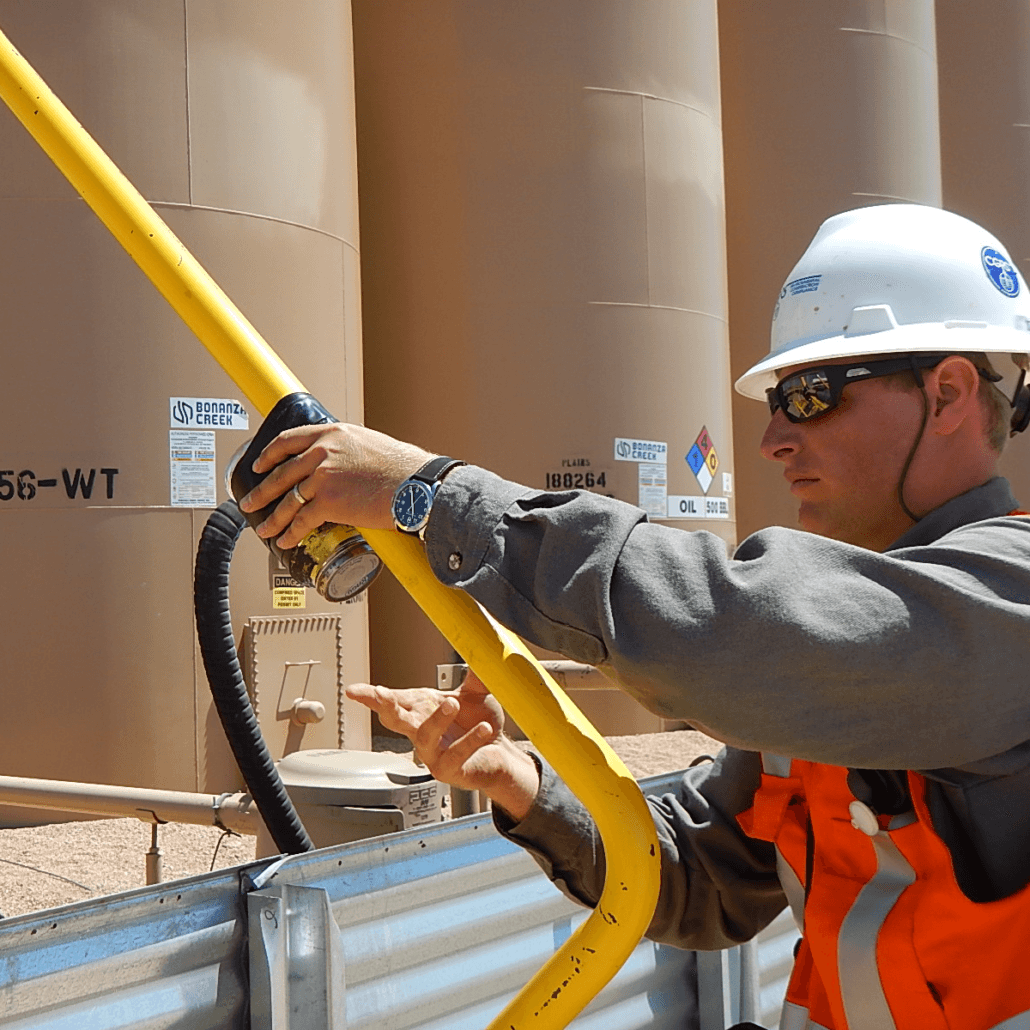

The state of Colorado, in its implementation of the LDAR program through Regulation 7, requires testing of compressor stations, tank batteries, and oil and gas wells to detect and repair components contributing to hydrocarbon emissions. Owners/operators can face stiff penalties if officials discover leaks during inspections. However, identifying and repairing leaks also helps protect the environment and is just good business practice. It increases the overall safety of the facility and prevents the loss of gas operators can otherwise sell for profit, as well.

Regulation 7 explains the required LDAR inspection frequency, which varies from a one-time inspection up to regular monthly inspections. The level of production often plays a big part in determining the required inspection frequency for a given facility. The recompletion of a well, resulting in an increase in production, or as production drops over time, for example, can move a facility into a different LDAR inspection frequency.

For many oil and gas production or gas compressor station owners, completing their own LDAR testing is just not cost effective, whether it’s the considerable investment in a FLIR camera, or finding, certifying and keeping an inspector on staff.

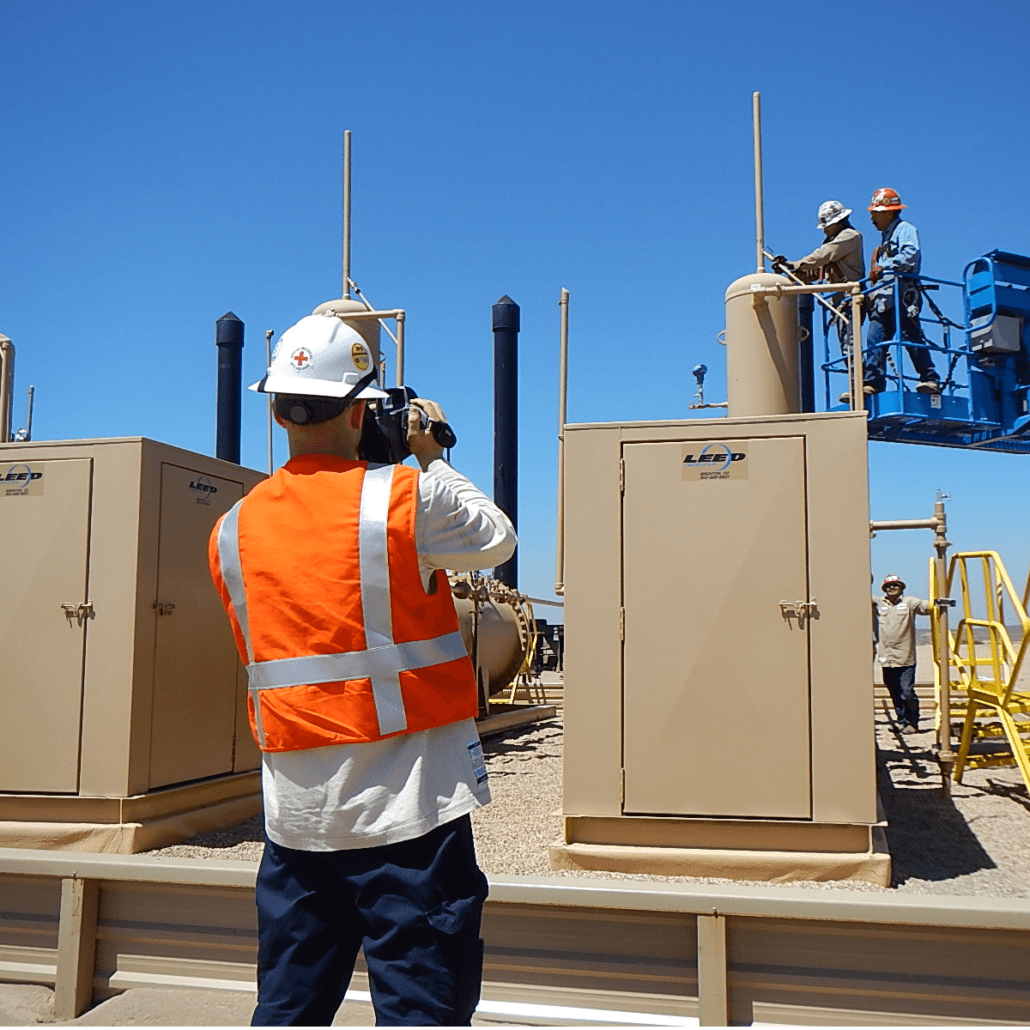

Not only does CGRS have the FLIR cameras and the certified inspectors, as well as the database to make regular and annual reporting simple, but we also have developed web-based software and real-time tablet communications specifically for tracking LDAR inspections. The software allows us to:

- Keep record and status of every leak and the due dates for repair and re-inspection

- Track the time required to repair each leak

- Know which repairs are on hold while a part is on order

- Schedule inspections and re-inspections

- Note that a shutdown is required to complete the repairs

CGRS technicians:

- Deliver a LDAR report to the client within 24 hours

- Provide a visual location of the leak with pictures

- Synchronize field data to the database

- Tag equipment at the leak and, if possible, add a mark clearly identifying it

- Records a video of the leak and makes it available to clients

CGRS’s knowledge of the LDAR regulations and facility equipment and our trained and experienced technicians allowed the client to transition seamlessly to a new vendor partnership with no interruption of compliance: CGRS now completes regular LDAR inspections to its dozens of northern Colorado facilities.

CGRS knows the regulations and has made LDAR testing simple for our clients.