Project Profile: Fuel System Installation

Greeley, Colorado

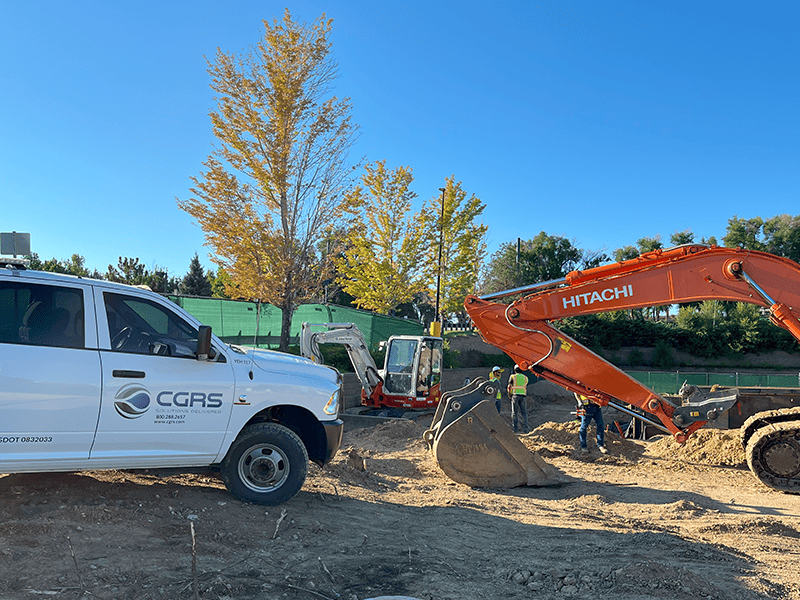

The Refined Fuels Construction team at CGRS recently completed the installation of a brand new, state-of-the-art fueling system for a major retailer in Greeley, CO. This project involved the integration of new fuel storage and dispensing infrastructure to enhance operational efficiency and ensure regulatory compliance.

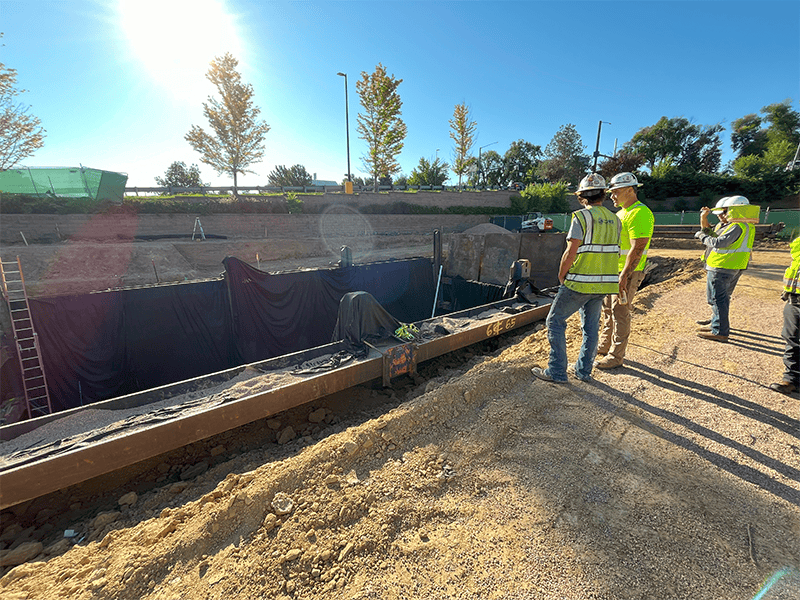

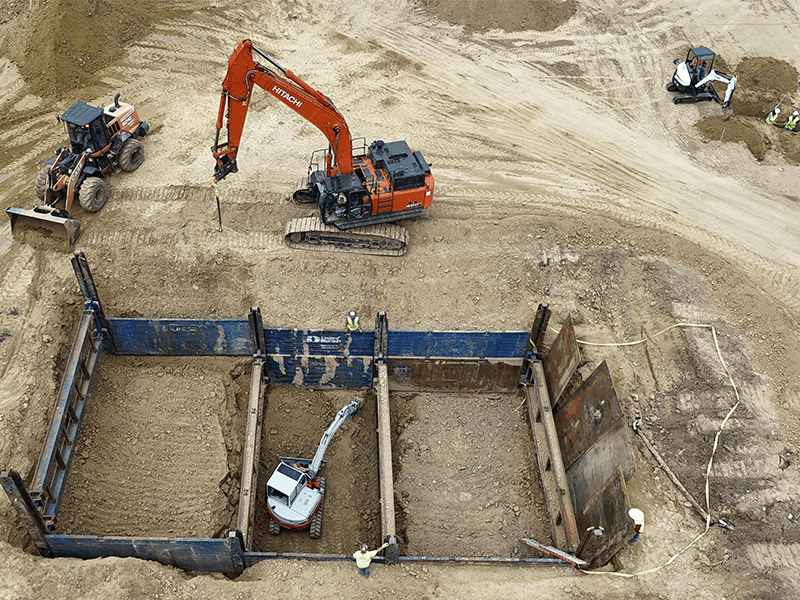

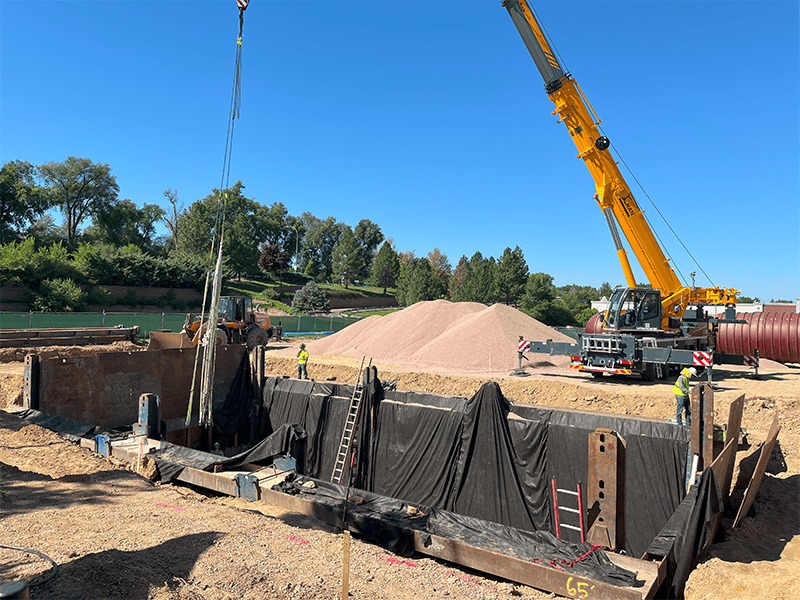

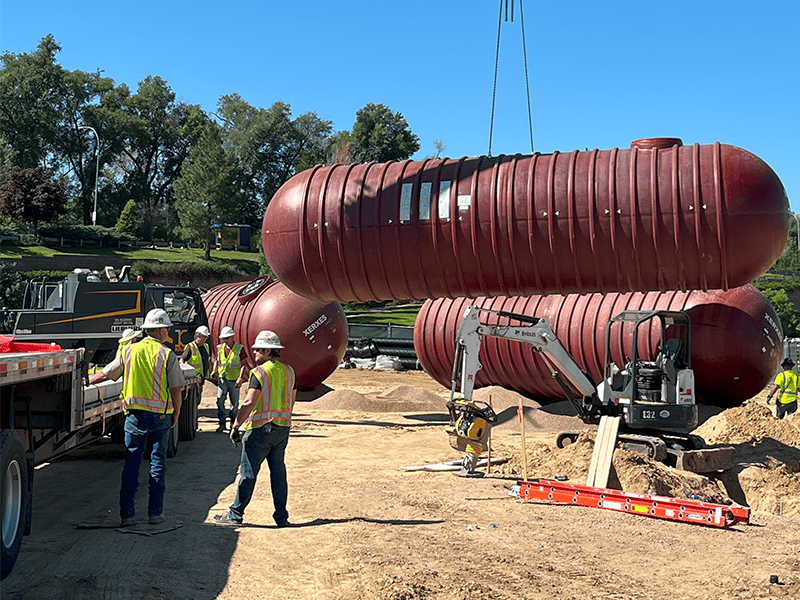

To initiate the project, CGRS, Inc. secured the necessary permits from the Division of Oil & Public Safety and fire jurisdictions to authorize the installation of the new fueling system. The team then excavated and stockpiled approximately 1,070 cubic yards of fill to accommodate a four-foot burial depth from the finish grade to the top of the underground storage tanks (USTs). Upon delivery, each UST was tested and inspected, anchored securely, and backfilled using pea gravel for optimal stability.

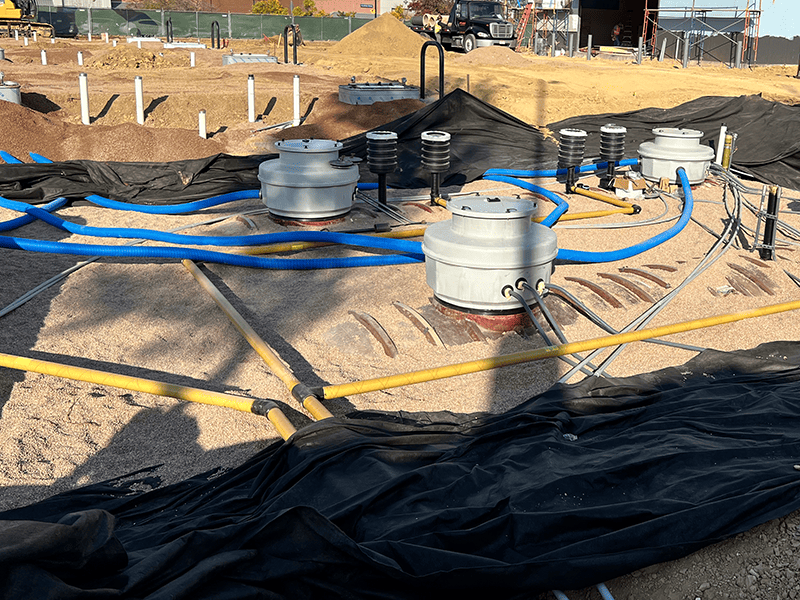

As part of the fueling system installation, eight under dispenser containers (UDCs) were installed to support fuel dispensing operations. Each UST was equipped with essential components, including submersible pumps, spill and overfill protection, containment sumps, vapor recovery risers, and tank inventory monitoring systems. The piping infrastructure included double-wall flexible piping from turbine sumps at the USTs, along with single-wall fiberglass-reinforced plastic (FRP) vent piping to facilitate safe fuel transfer.

Call a CGRS Expert:

800.288.2657

Drew Higgins

Director of Fuels

Mobile: 970.420.3493

Comprehensive testing was conducted to ensure system integrity. All sumps and UDCs underwent hydrostatic testing at a level two inches above the highest penetration point, while spill containers were also subjected to hydrostatic testing. Final inspections were performed by OPS and the local fire department to ensure compliance with all applicable regulations. Once testing was completed, the USTs, vent, and product lines were backfilled to sub-grade using pea gravel. Manways were installed as needed over the UST containment areas.

To complete the installation, fuel dispensers were positioned and secured onto the UDCs, ensuring proper connection to the product piping. Electrical connections were finalized by a third-party contractor, bringing the fueling system to full operational status. The newly installed system is now fully functional and ready to support the fueling needs of the community.