FUEL-QUALITY SERVICES

Problems with water and degraded fuel in underground tanks can be a costly nightmare for fuel retailers and commercial fuel users. CGRS and our partners provide a comprehensive solution for removing water from fuel reserves as well as a complete tank-cleaning and fuel-restoration service to ensure premium quality for all fuel types – including gasoline products and diesel – at all times.

Our comprehensive solution includes removing water, particulate and biological contamination from fuel reserves, as well as a complete tank cleaning and fuel restoration service for our longtime clients; biocide and fuel conditioners are added as necessary.

Our cleaning technology sweeps the tank to remove only contaminates and water; all of the fuel remains in the tanks.

CGRS provides full documentation on the cleaning, as well as product quality reports and fuel inspection report on all tanks on site.

Our water pump-out and fuel-restoration services means you can manage:

- Water issues including phase separation

- Costly insurance claims from vehicles breaking down

- Bacterial and fungal activity

- Problems with blocked filters

- Malfunctioning pumps and automatic tank gauges

- Power outages with critical emergency power backup systems

- Costly replacement of degraded fuel stock

Fuel Sampling & Analysis

How do you know if your fuel is off spec? We can take fuel samples from anyplace along the supply chain, from refinery to vehicle, to identify where contamination problems exist. Samples sent to the lab can be analyzed for particulate, water, bacteria, re- polymerization and more, depending on the situation. We provide solutions to fit each situation.

Filtration

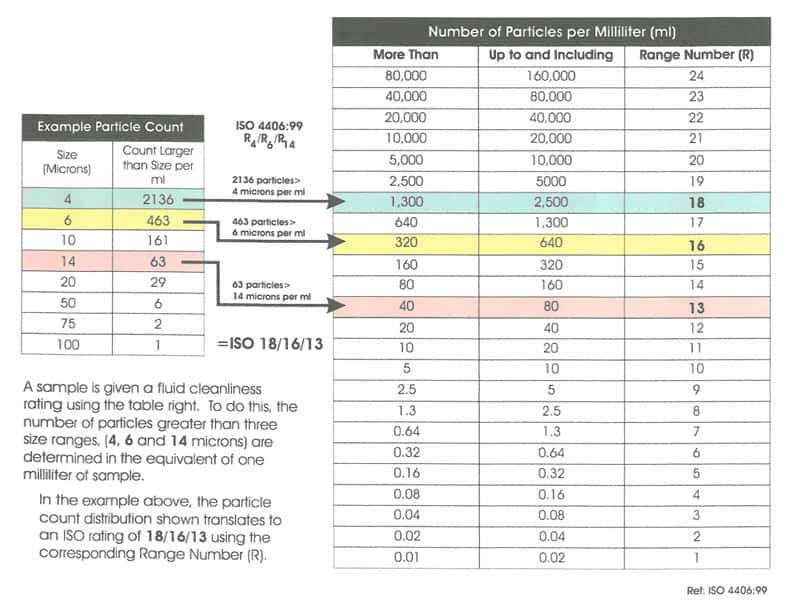

CGRS can provide you with all your filtration solutions. That 30 micron filter you have out at the dispenser will no longer cut it. To meet the ISO 4406 standard you have to filter to 4 micron. Properly sized filtration is key to ensure fuel quality, minimize downtime and filter blowouts.

Meeting the ISO 4406 Diesel Fuel Standard

The EPA passed regulations to reduce emissions from diesel engines. Manufacturers have released new engines to comply with these regulations. These common rail engines operate at a significantly higher pressure — up to 30,000 psi — and require fuel that meets the ISO 4406 particulate standard. Out of spec fuel can plug vehicle fuel filters, cause filter blowouts, injector damage and can potentially void your warranty.

Tier 4 Diesel Engines

Many industries including trucking, railroads, mining, power generation, back-up power generators and automobiles us diesel engines. New engines operate at a significantly higher pressure. Poor fuel quality causes erosive and abrasive wear in these engines leading to premature component failure and costly downtime. The cost of failure includes repairs to the engine, lost production, unplanned downtime and, in critical diesel applications like back-up generator systems at a hospital, can also endanger lives.